Charter Classic 1.5m Kit

Express delivery

Large selection of carriers

Satisfaction guarantee

Package contents

Laser-made wooden parts of the Charter Classic aircraft model, 1: 1 plan, detailed construction instructions with step-by-step pictures.

Characteristics

Kit of the wooden model Charter Classic with a span of 1.47 m in spreading. A light training model made of balsa and plywood is built on a plan in a 1: 1 scale. The model is designed to be driven by an electric motor with front mounting. Discover the world of model design and build your own aircraft.

Charter Classic is a kit of a training all-wood upperplane, which is designed for piloting training. It allows flying with ailerons, thanks to its upper surface concept it is a guarantee of good unmistakable flight characteristics. The rudder, elevator, ailerons and engine are controlled. An intuitive image manual guides you through building the model and installing the electronics.

Properties

- A classic kit for those who want to build an airplane themselves

- Thanks to the construction plan in a 1: 1 scale and detailed pictorial instructions, even less experienced modelers can assemble

- Precisely laser-cut parts from poplar plywood and balsa

- Small accessories in the package

Wing construction

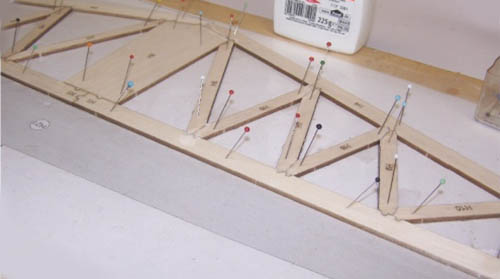

In the kit you will find finished wooden components, such as ribs, beams, partitions, moldings and the like. These are gradually glued according to the instructions with a suitable wood glue (eg dispersion or strength Epoxy kits), the work goes quickly by hand and in the afternoon you can have the sash glued together.

Hull construction

The fuselage connects the wing and tail surfaces into one functional unit and is therefore the most complex part of the aircraft model. It contains control electronics, drive unit and battery. The construction will undoubtedly be managed by anyone who will follow the logical progress of work according to the picture manual. The assembly of the fuselage is performed in stages, when the individual structural nodes are glued together and the individual components are gradually added until the fuselage is completed by the final work related to the installation of servos and propulsion.

Tail surfaces

The construction of the tail surfaces is very simple and is built directly on the plan. In order not to damage the plan during gluing, it is advisable to put a transparent foil on it.

Tail rudder servos

The elevator and rudder have servos located in the fuselage under the wing and the rods transmit the movement of the servo levers to the rudder levers.

Chassis assembly

The aluminum legs are attached to the fuselage with three screws, the wheels and connecting material are in the kit package.

We recommend buying

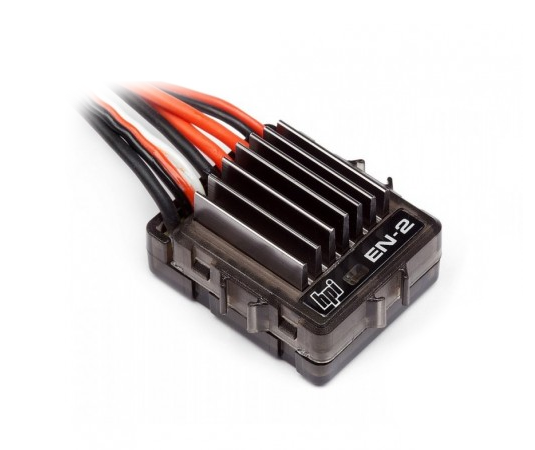

It is a classic all-wood kit. To assemble the model, you need suitable adhesives, basic modeling tools and coating foil. We recommend using an iron-on foil to coat the model. There is no electronics in the package, so you need to buy an AC motor, propeller, regulator, battery and 4 mini servos and a 4+ channel RC kit. It is recommended to read the manual, see Support

To build a model you need:

- Thin instant glue or non-toxic Super Fatic from Deluxe Materials

- White PVA glue or sandable yellow aliphatic for wood

- Epoxy glue - 5 minutes

- Coating foil

The construction of wooden aircraft models is a traditional and the oldest technology used in their production. Wood is an affordable and inexpensive material, it is flexible, light and extremely durable. The structure can be repaired in case of damage. Beam slats are used as the material, most often spruce, pine, the basic building material is balsa and various types of plywood. Beech, ash or blocks of arms, linden, etc. can be used for strength parts.

GLUING OF WOODEN COMPONENTS

The plan is placed on a flat wooden worktop made of soft wood (lath), on the plan it is necessary to place a transparent foil that will protect the plan from adhesives. For gluing, we use model pins KR-490050 which fix the components in the exact position. Conventional gluing of wooden parts is glued with dispersion glue FS-G09 / 250 or DM-AD10, which have the advantage of slow drying, so there is enough time to assemble the structure. The glued structure can be removed the next day after gluing.

STRENGTH ADHESIVE

During construction, there are several structural units that need to be glued with adhesives that resist higher stress, are resistant to chemicals, water, etc. The best known are 2-component Epoxy adhesives, supplied in a smaller package DM-AD67, in a larger package DM-AD68 and for extra high strength DM-AD19.

QUICK ADHESIVE

When working, it is sometimes necessary to use fast and firm bonding of components, for which second cyanoacrylate adhesives are excellent.

Gluing aids

Our hands are not enough everywhere and when assembling a large number of parts separately, therefore various types of clamps are a welcome helper. Model mini stiffeners SH-PCL3050, parallel clamps SH-PCL4201 / A, classic clamps SH-PCL3000 or flexible clamps SH-PCL8710 / 2

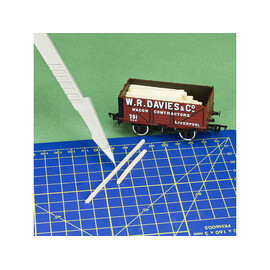

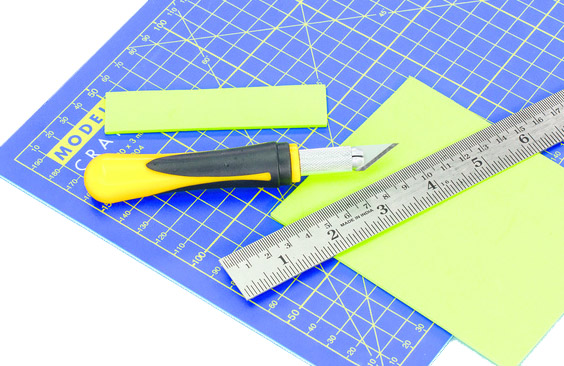

Cutting tools

When working with different materials, you need knives, saws, scissors and a lot of other tools. We can recommend break-off knives SH-PKN1003, set of knives SH-PKN3305 / S, model saws fine SH-PSA35 / 300 or larger SH-SA35 / 380, special straight scissors NA3528 or curved scissors NA3527

Modeling tools and pad

For precise cutting, gluing of parts and also as protection of the table, we recommend the modeling pad SH-PKN6003 and the safety ruler SH-RU1774.

Coating foils

The fastest and most effective surface treatment of wooden models is the coating with iron-on foil. IronOnFilm Not only is it possible to choose from a whole range of color shades, but it also solves the carcass resistance to weathering, color and shape stability, easy repairability and speed when completing the model. To work, you need a model iron, a sharp model knife and scissors.